Not All Vinyl is Equal: A Business Owner's Guide to Vetting a "Wrap Shop Near Me"

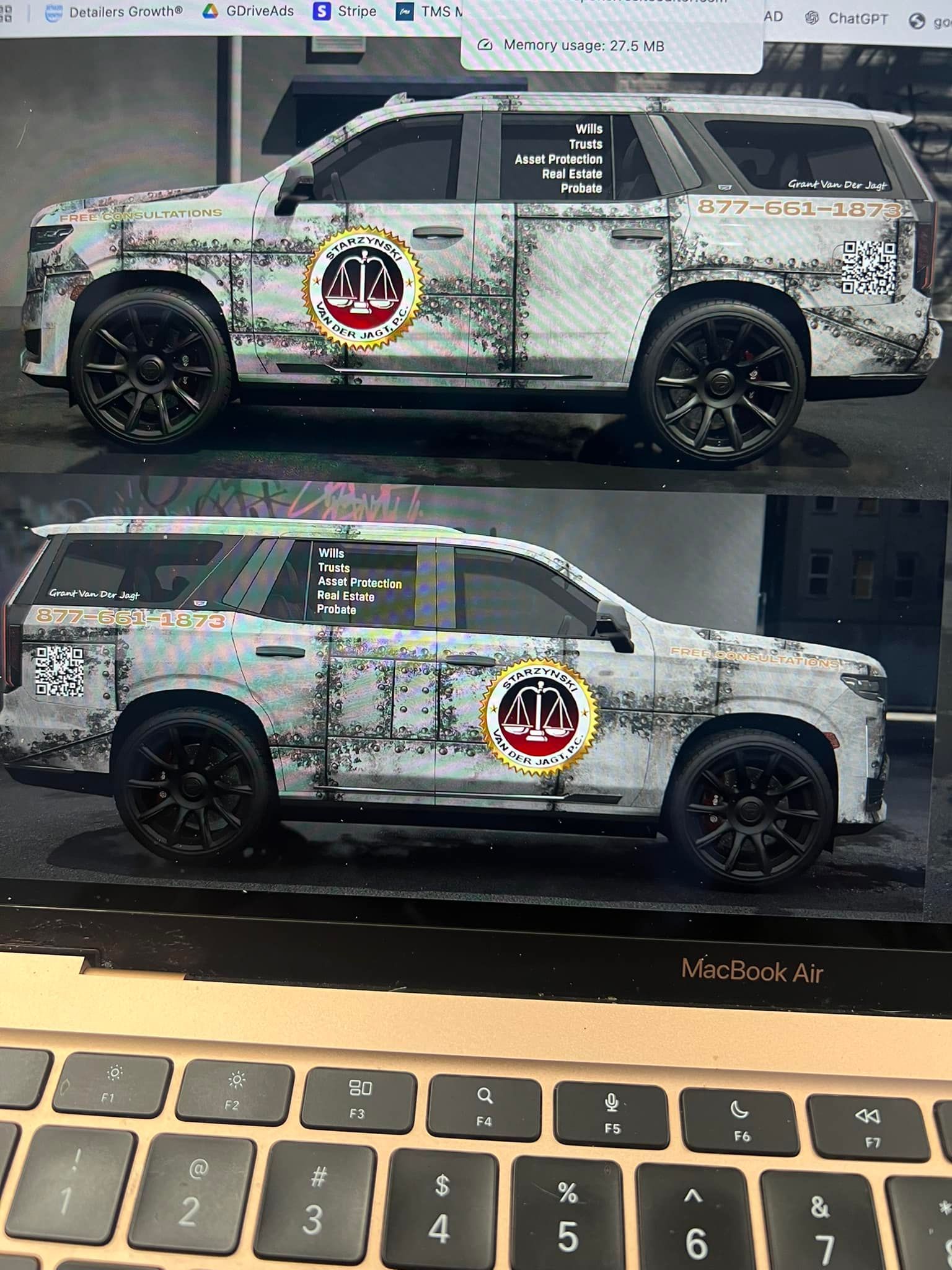

When you search for a "wrap shop near me," you're not just looking for a product; you're looking for a long-term partner to represent your brand. A commercial vehicle wrap is a powerful investment. Done right, it transforms your fleet into a 24/7 lead-generation machine. Done wrong, it can peel, fade, and bubble, making your brand look unprofessional and costing you more in the long run.

The final price quote is only one part of the equation. To protect your investment, you need to vet the process and the materials. As a certified commercial wrap expert in Wheat Ridge, CO, we believe an educated customer is the best customer. Here are the critical factors you must ask about before choosing your local wrap shop.

1. The Material Question: Cast Vinyl vs. Calendered Vinyl

This is the most important question. Not all vinyl is created equal.

- Calendered Vinyl: This is a cheaper, thicker material. It is more prone to shrinking over time, which can lead to peeling edges, cracking, and adhesive failure. It is best suited for flat, short-term signage, not vehicles.

- Cast Vinyl: This is the premium, professional-grade material. It is manufactured to be thinner, more durable, and dimensionally stable. It conforms beautifully to the complex curves of a vehicle (like mirrors and bumpers) without shrinking. It also allows for clean, long-term removal that protects your paint.

What to ask: "What specific brand and type of vinyl do you use for commercial wraps?"

A professional shop's answer: We use premium cast vinyl exclusively, from industry leaders like 3M and Avery Dennison. This ensures your fleet branding will last 5-7+ years and won't damage your vehicle.

2. The Environment Question: "Is Your Shop Clean & Controlled?"

A car wrap's biggest enemy is dust, hair, and debris. A single speck of dust trapped under the vinyl creates a permanent, visible blemish.

A low-cost installer might work in an open, dusty warehouse or even a mobile tent. This is a major red flag. A professional wrap shop operates in a clean, well-lit, and temperature-controlled installation bay. This controlled environment is essential for a flawless, paint-like finish.

What to ask : "Can I see your installation bay? What is your process for preparing the vehicle?"

A professional shop's answer: Our process involves a multi-step decontamination wash before the vehicle even enters the bay. We then perform the installation in a dedicated, clean, and climate-controlled environment to guarantee zero contamination.

3. The Process Question: "Do You Cut on the Car?"

This is a critical, technical question. An inexperienced installer may lay a large sheet of vinyl on the vehicle and trim it to size with a razor blade directly on your paint. This can lead to permanent, deep scratches in your clear coat that you won't discover until the wrap is removed years later.

A modern, professional shop avoids this risk by using two key methods:

- Plotter-Cut Graphics: For vinyl lettering and logos, a computer-controlled plotter cuts the design precisely before it's applied.

- Vehicle Templates: For full wraps, we often use advanced software with digital templates of your exact vehicle model. This allows us to pre-cut panels for a perfect fit with minimal-to-no on-vehicle trimming.