Innovative Techniques in Custom Printing for Vehicle Wraps

This is a subtitle for your new post

Innovative Techniques in Custom Printing for Vehicle Wraps

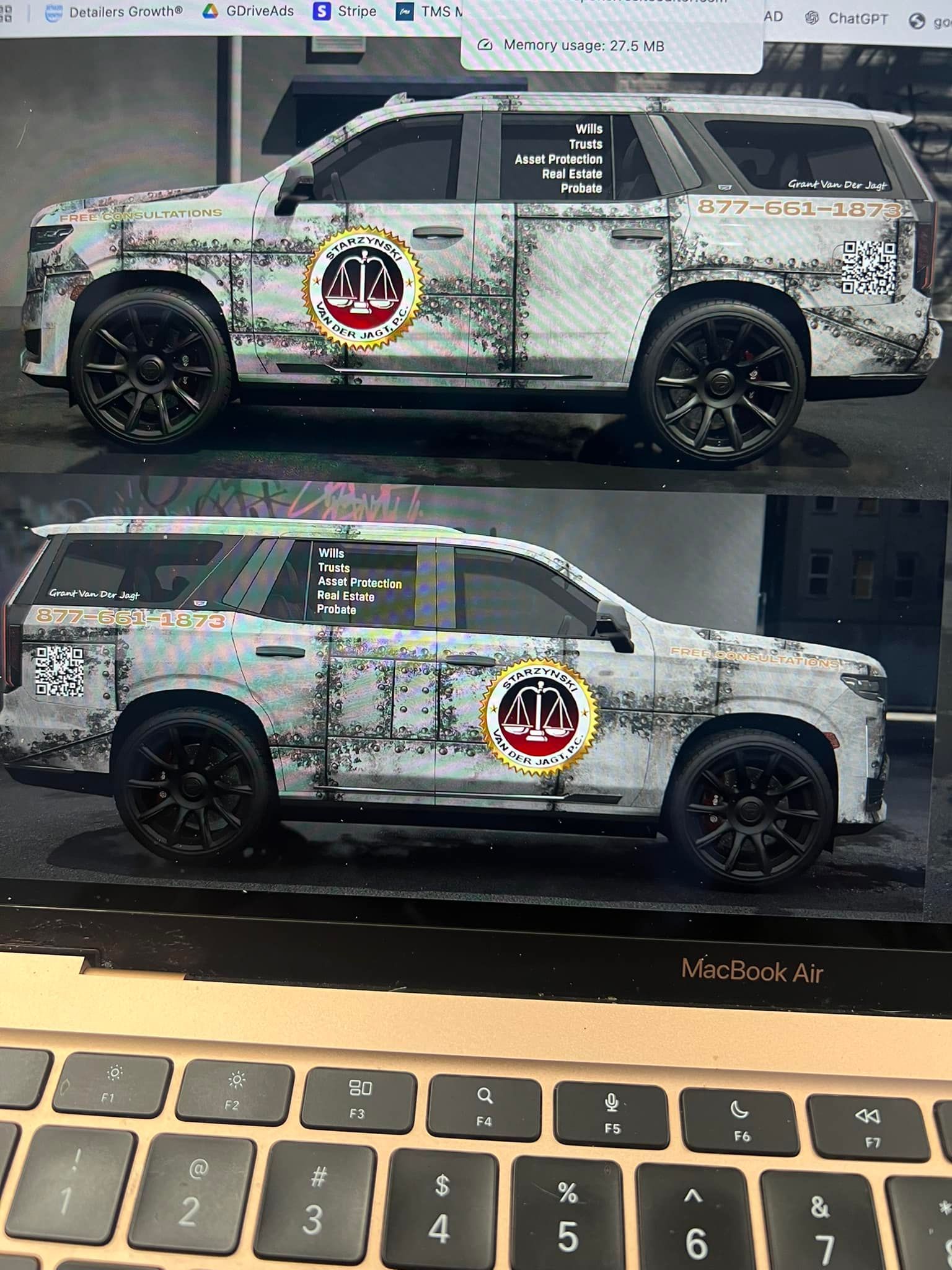

In the world of advertising, vehicle wraps have emerged as a dynamic and eye-catching way to promote brands. Custom printing for vehicle wraps allows businesses to turn their vehicles into mobile billboards, reaching a vast audience wherever they go. As technology evolves, so do the techniques used in custom printing, making it easier to create stunning and effective wraps. In this comprehensive guide, we will explore the innovative techniques in custom printing for vehicle wraps, how these advancements enhance designs, and what they mean for businesses looking to make a statement on the road.

## Understanding Vehicle Wraps

### What Are Vehicle Wraps?

Vehicle wraps are large vinyl graphics or decals applied to the exterior of a vehicle. These wraps can cover the entire vehicle or just specific areas, such as the doors, hood, or rear. Vehicle wraps serve as a cost-effective advertising solution, allowing businesses to promote their brand, products, or services while on the move.

### The Benefits of Vehicle Wraps

1. **High Visibility**: Wraps turn vehicles into moving advertisements, increasing brand visibility and reaching a wide audience.

2. **Cost-Effective Marketing**: Compared to traditional advertising methods, vehicle wraps provide long-lasting exposure at a lower cost over time.

3. **Professional Appearance**: A well-designed wrap enhances your business's image, projecting professionalism and credibility.

4. **Flexibility**: Vehicle wraps can be easily updated or changed, allowing businesses to adapt their messaging as needed.

5. **Protection**: Wraps can protect the vehicle's paint from scratches and UV damage, preserving its resale value.

## Innovative Techniques in Custom Printing

As the demand for high-quality vehicle wraps grows, so does the technology behind custom printing. Here are some of the most innovative techniques that are shaping the future of vehicle wrap printing:

### 1. Digital Printing Technology

Digital printing has revolutionized the way vehicle wraps are created. Unlike traditional printing methods, digital printing allows for high-resolution images and intricate designs to be printed directly onto vinyl materials. Here’s why digital printing is a game-changer:

- **High Resolution**: Digital printing produces sharp, vibrant images that can include intricate details and gradients, making wraps more visually appealing.

- **Customization**: Digital printing allows for easy customization. Businesses can create unique designs tailored to their brand without the limitations of traditional printing.

- **Quick Turnaround**: Digital printing offers faster production times, enabling businesses to get their wraps on the road quickly.

### 2. Eco-Friendly Inks

With increasing awareness of environmental issues, many printing companies are turning to eco-friendly inks for vehicle wraps. These inks are designed to reduce harmful emissions and lessen the environmental impact. Here’s why eco-friendly inks are beneficial:

- **Safety**: Eco-friendly inks are often non-toxic and safer for both the environment and the workers involved in the printing process.

- **Vibrant Colors**: Advances in eco-friendly ink technology have led to improved color vibrancy and durability, ensuring that vehicle wraps look just as stunning as those printed with traditional inks.

- **Sustainability**: Using eco-friendly inks aligns with sustainability goals, appealing to environmentally-conscious consumers.

### 3. Advanced Adhesive Technology

The adhesive used in vehicle wraps is crucial for ensuring a strong bond between the wrap and the vehicle's surface. Innovative adhesive technologies have improved the performance of vehicle wraps significantly:

- **Air Release Technology**: This adhesive technology allows for the easy installation of wraps without bubbles. The air release feature enables air to escape during the application process, resulting in a smooth finish.

- **Removability**: New adhesives are designed to be removable without damaging the vehicle's paint. This is especially important for businesses that may want to update their wraps frequently.

- **Durability**: Advanced adhesives provide better resistance to weather conditions, ensuring that wraps stay intact for longer periods.

### 4. 3D Printing Techniques

3D printing is making its way into the vehicle wrap industry, allowing for unique textures and designs that were previously impossible to achieve. Here’s how 3D printing is innovating vehicle wraps:

- **Textured Wraps**: 3D printing can create textured surfaces that add dimension to wraps. This can enhance the visual appeal and make wraps stand out even more.

- **Custom Shapes**: 3D printing allows for custom-shaped graphics that can contour to the vehicle’s curves, providing a more seamless look.

- **Increased Engagement**: Textured wraps can attract more attention and engage potential customers by providing a tactile experience.

### 5. Specialty Finishes

Specialty finishes are becoming increasingly popular in vehicle wraps. These finishes can add an extra layer of uniqueness to the design. Some of the most popular specialty finishes include:

- **Matte Finishes**: Matte wraps provide a sleek, modern look that stands out from traditional glossy finishes. They can give vehicles an understated elegance.

- **Metallic Finishes**: Metallic wraps add a shiny, reflective quality to the design, making it eye-catching and vibrant.

- **Chrome Finishes**: Chrome wraps create a flashy, attention-grabbing effect that is sure to turn heads. They are often used for high-end vehicles or promotional campaigns.

### 6. Print and Cut Technology

Print and cut technology allows for the combination of printed graphics and cut vinyl, creating versatile designs. Here’s how this technique works:

- **Precision Cutting**: With print and cut technology, graphics can be printed and then precisely cut to shape. This allows for intricate designs that can include custom lettering and logos.

- **Layering Effects**: This technique enables the layering of different materials and finishes, creating depth and texture in the design.

- **Cost Efficiency**: Print and cut technology can be a cost-effective solution for businesses looking to create custom designs without breaking the bank.

### 7. Wrap Design Software

Advancements in design software have also improved the vehicle wrap process. Modern design software allows for more efficient creation and visualization of wrap designs:

- **3D Visualization**: Many design software programs offer 3D visualization tools that allow businesses to see how their wraps will look on actual vehicles before production begins.

- **Template Library**: Design software often includes a library of vehicle templates, making it easier for designers to create wraps that fit specific vehicle models.

- **Collaboration Features**: Many software programs allow for collaboration among team members, enabling input and feedback throughout the design process.

## The Custom Printing Process

Now that we’ve explored the innovative techniques in custom printing for vehicle wraps, let’s take a closer look at the typical custom printing process:

### Step 1: Consultation and Concept Development

The first step in creating a vehicle wrap is a consultation with a professional designer. During this phase:

- **Understanding Goals**: The designer will discuss your goals, target audience, and branding to develop a concept that aligns with your vision.

- **Design Inspiration**: You can provide inspiration or examples of designs you like, helping the designer understand your preferences.

### Step 2: Design Creation

Once the concept is established, the designer will create the initial design.

- **Graphic Design**: The designer will use graphic design software to create the wrap design, incorporating your branding elements, colors, and messaging.

- **Client Feedback**: You will have the opportunity to review the design and provide feedback. This collaborative process ensures that the final design meets your expectations.

### Step 3: Printing and Production

After finalizing the design, the printing and production process begins.

- **Material Selection**: High-quality vinyl and eco-friendly inks will be selected for the printing process.

- **Printing**: The design is printed using advanced digital printing technology, ensuring vibrant colors and sharp details.

- **Cutting**: If using print and cut technology, the graphics are cut to shape for a precise fit.

### Step 4: Installation

Once the printed materials are ready, it’s time for installation.

- **Surface Preparation**: The vehicle’s surface is thoroughly cleaned to ensure optimal adhesion.

- **Professional Installation**: An experienced installer applies the wrap, using air release technology to ensure a bubble-free finish.

- **Final Inspection**: After installation, a final inspection is conducted to ensure everything looks perfect.

### Step 5: Maintenance and Care

To ensure the longevity of your vehicle wrap, regular maintenance is essential.

- **Cleaning**: Use mild soap and water to clean the wrap regularly. Avoid harsh chemicals that could damage the vinyl.

- **Protection**: Consider applying a protective wax designed for vinyl wraps to enhance their shine and provide added protection against UV rays.

## Conclusion

Innovative techniques in custom printing for vehicle wraps are revolutionizing the way businesses advertise on the road. From digital printing technology and eco-friendly inks to advanced adhesive applications and specialty finishes, these advancements allow for stunning, high-quality wraps that effectively promote brands.

By understanding these innovative techniques and the custom printing process, businesses can make informed decisions when investing in vehicle wraps. The benefits of high-quality wraps—such as increased visibility, cost-effective marketing, and professional appearance—make them a valuable addition to any marketing strategy.

At Ikonic Detailing, we are committed to providing exceptional vehicle wraps that elevate your brand and help you stand out in a competitive market. Contact us today to learn more about how our innovative printing techniques can transform your vehicles into powerful advertising tools!