Is Your Fleet Driving Around Wearing an Invisibility Cloak?

If a potential customer in Denver or Wheat Ridge passed one of your work trucks on the highway right now, would they know you exist?

For many service businesses, the answer is "no." A plain white work van is functionally invisible. It blends into traffic, missing countless opportunities to make an impression. Even worse, an unmarked vehicle pulling up to a client's home creates a subconscious moment of doubt: "Is this a legitimate business?"

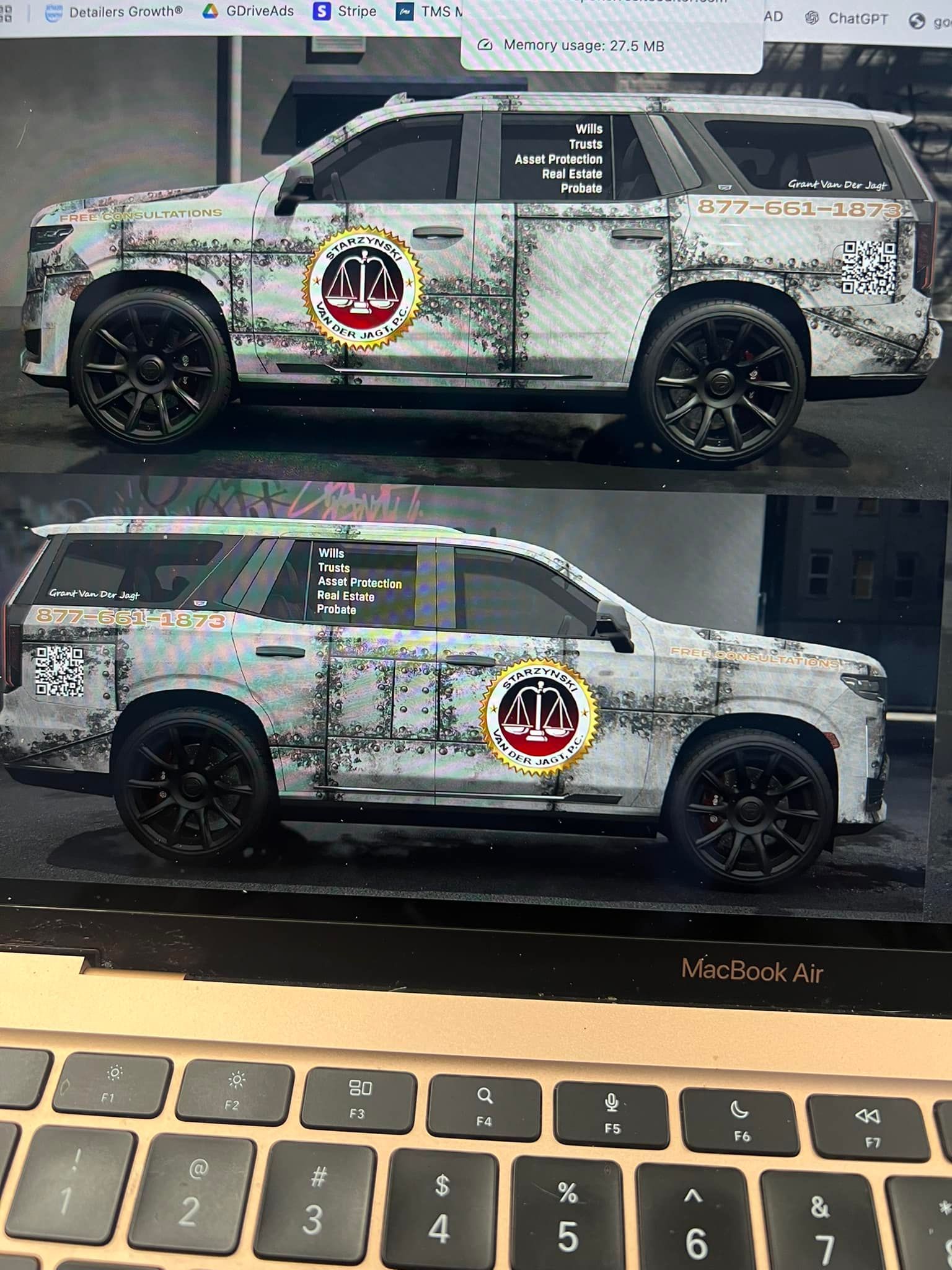

A professional commercial fleet wrap is the opposite of an invisibility cloak. It is a uniform for your business. It instantly communicates legitimacy, establishes trust before you even knock on the door, and ensures that every mile your team drives is a marketing opportunity.

In this guide, we will break down the factual, financial, and operational reasons why transforming your fleet is the smartest investment you can make this year.

1. The Financial Math: Stop Renting Your Advertising

Why are you still paying monthly fees for billboards or digital ads that disappear the moment you stop spending? There is a smarter way to dominate the local market.

Most local advertising is a rental agreement. You pay for temporary space or fleeting clicks. Vehicle advertising is fundamentally different: it is a one-time capital investment in an asset you own.

Once installed, a commercial wrap works for you 24/7 for the next 5-7 years with zero recurring costs. When you analyze the data, a wrapped vehicle in a busy metro area like Denver generates between 30,000 and 70,000 impressions daily.

This results in the lowest Cost-Per-Impression (CPI) of any major advertising medium—far lower than radio, TV, or pay-per-click. It is the only marketing strategy where the ROI improves every single day the vehicle is on the road.

2. Busting the "Downtime" Myth

We hear it constantly from business owners: "I know I need to wrap my fleet, but I can't afford to have my trucks off the road."

This is the biggest myth holding businesses back from professional fleet branding. The factual reality is that a true pro wrap shop understands that your vehicles need to be earning revenue. We have engineered our process to minimize downtime.

- Design & Print First: All creative work, digital proofing, and material production happen while your vehicles are still out working.

- Staggered Scheduling: We don't wrap your whole fleet at once. We cycle vehicles through one or two at a time.

- Strategic Timing: We utilize weekends or overnight drops to ensure your team doesn't miss a beat.

A professional wrap installation is a logistical process, not just an art project. Do not let the fear of downtime stop your growth.

3. The Hidden Benefit: Increasing Resale Value

Most people think a commercial wrap is just a giant sticker for marketing. Smart fleet managers know it’s actually a suit of armor.

Work trucks in Colorado take a beating. Gravel from I-70, intense high-altitude UV rays, and corrosive road chemicals (like magnesium chloride) destroy your paint.

This damage significantly lowers the vehicle's trade-in value when you are ready to upgrade.

A premium vinyl wrap (using cast vinyl from 3M or Avery Dennison) acts as a sacrificial shield. For 5 years, the wrap takes the abuse, leaving the factory paint underneath completely untouched.

When it's time to sell or trade the vehicle, we professionally remove the wrap to reveal pristine, showroom-quality paint. A fleet wrap is a rare business investment that serves two functions: it generates leads today and protects your asset's value for tomorrow.

4. How to Vet a "Wrap Shop Near Me

You’ve decided your business needs the visibility of a commercial wrap. Now you face the most critical decision: who will install it?

Searching for a "wrap shop near me" will give you many options, but a low price often hides costly shortcuts. A professional custom wrap requires three non-negotiable elements to survive the Colorado climate:

- Premium Materials: Always ask if the shop uses Cast Vinyl. Cheaper "Calendered" vinyl will shrink and crack within a year. We exclusively use premium films from industry leaders.

- Climate Control: An installation bay must be kept at a specific temperature (typically 65-75°F) for the adhesive to bond correctly. If a shop is dusty or cold, the wrap will fail.

- Meticulous Prep: A wrap only sticks to a surgically clean surface. Our multi-stage decontamination process removes tar, iron, and wax to ensure a permanent bond.